Another day, another interesting idea. The ideas were not from my own brain, of course, but from the minds of others. A recent trip to the IEEE Photovoltaic Specialists Conference (PVSC) in Tampa led to both ingredients mentioned by Einstein in his recipe for genius: inspiration (from conference speakers) and perspiration (from Tampa weather). Although all of us PVINers had some talks to attend on technology related to our specific research, it was often in the talks on “Fundamentals and New Concepts for Future Technologies”, or “Area 1”, that one found new ideas that could potentially be applied to a wide-variety of technology bases. This was so much the case, that “when in doubt, go to Area 1” became a mantra. Such wandering brought me to the talks on “up-conversion” and “down-conversion”.

Up-Conversion and Down-Conversion of Photons

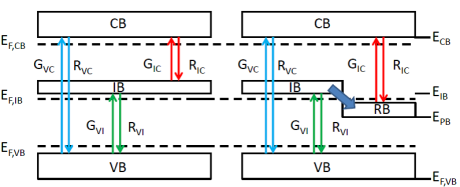

The conversion of photons of one frequency to those of a different frequency is referred to as either up- or down-conversion. This new frequency can either be a higher frequency (“up-conversion”), or lower frequency (“down-conversion”). A fluorescent material that absorbs UV light and emits visible light is a good example of a down-converter. Down conversion is more readily accomplished, as energy conservation allows (in fact, requires) energy to be lost during the conversion process (through heat, for instance). Up-conversion, however, requires additional energy. In the cases described in the talks at IEEE PVSC, this energy was supplied by a second photon. As an example, the first photon excites the electron into an intermediate state, while the second photon excites the electron from the intermediate state into an even higher energy state. The subsequent decay results in an emitted photon of higher frequency than the initial two photons.

Photon Conversion in Photovoltaics

So why do we care about these types of effects and the materials that exhibit them? In photovoltaics, there are two main reasons:

1. Wavelengths below the band gap of the absorbing layer will not generate carriers.

2. Very short wavelengths are readily absorbed by transparent conducting oxide (TCO) or other buffer layers before they reach the absorber layer.

To address the first issue, up-conversion is a potential approach, while the second can be resolved with a down-conversion.

I found three of the talks given at IEEE PVSC specifically on the topics of up- and down- conversion in photovoltaics particularly engaging. Four talks if you count the excellent plenary talk by Dr. Ekins-Daukes [1]. The first talk was on using up-conversion in erbium-doped yttrium fluoride to increase the photocurrent of silicon solar cells; The second talk was on using quantum well islands (QWIs) as up-converters in InGaAs cells, and the third was about using quantum dots (QDs) as down-converters in GaAs solar cells.

A New Quantum Efficiency Record: Erbium-doped Hexagonal Yttrium Fluoride

In the first (and probably my favorite) talk, Stefan Fischer of the Fraunhofer Institute described some of his work involving the use of trivalent erbium-doped hexagonal yttrium fluoride as an up-converter [2]. This material exhibits at a wide range of wavelengths close to 1523 nm and the resulting emission is primarily of light with a wavelength of 980 nm. Other radiative emission lines occur at 540, 655, and 805 nm. When a sample was illuminated using a 1523 nm laser, the conversion efficiency was about 2.8%. Although that might not seem like much, said quantum efficiency was acknowledged as a new record during the presentation and is a result of some significance. This presentation was given the award of “Best Student Presentation” for Area 1, and I suspect that said result was a major reason why. Silicon does not readily absorb light that has a wavelength of more than 1130 nm. Because trivalent erbium-doped yttrium fluoride is very good at converting photons of wavelengths longer than can be absorbed (~1523 nm) to those of a wavelength that can be absorbed (~980 nm), it has potential use as an up-converter in silicon photovoltaics. When used in said solar cells, the material will be under broad-band (and not laser) illumination. As such, they characterized the absorption and emission under several different illumination scenarios and then calculated the potential increase in current. Although the conversion efficiency drops in broad band cases, the predicted improvement in generated current increases. This was especially true under concentrated illumination. Direct experimental measurement of the improvement achieved in silicon solar cells using this up-conversion technology is ongoing.

Quantum Well Islands

In the second talk, Itaru Kamiya of the Toyota technological institute described an InGaAs up-conversion technology based on InAs quantum dots [3]. By “under-growing” the QDs (2-3 monolayers), they got broader, shallower structures they termed quantum-well islands. When illuminated by 855 nm light, such islands exhibit emission at around 725 nm, demonstrating that the islands facilitate up-conversion. Unlike in the previous talk where the up-conversion layer is intended to be outside the cell, the QWIs are embedded right in the middle of the absorber structure. An additional difference is that their hypothesized conversion mechanism involves excitons and Auger recombination rather than an electron being directly excited by the additional photons to a higher energy state. In this model, two separate excitons are generated by the longer wavelength light. The energy of one exciton is then transferred to the second exciton via an auger interaction. This additional excitation allows the carriers to “escape” into the absorber layer. However, further collection of evidence to support this hypothesized mechanism is required.

Down-Conversion using Quantum Dots

The final talk on photon conversion was given by Hau-Vei Han of National Chiao Tung University. In it, he described an experiment in which quantum dots were deposited on the surface of a GaAs photovoltaic cell in order to both enhance the anti-reflection (AR) properties of the solar cell and to act as a down-converter [4]. They demonstrated that a broad spectrum efficiency enhancement was observed due to AR improvements, and additional efficiency improvements were observed in the UV region. This additional improvement in the UV is currently thought to be due to down-conversion from the QDs. Although there was a significant improvement in the overall cell efficiency, it appears that this is mostly due to improvements in the AR-properties, with the down-conversion playing only a minor role.

Overall, it was nice that each talk demonstrated a different approach to photon conversion in photovoltaics. This allowed me to get some insight into how one might implement conversion in a wide-variety of architectures, and also highlighted some of the potential areas for improvement and further study. I strongly recommend you take a look at the manuscripts given in the references once the conference proceedings are published.

As for me, I’ll be taking some time to investigate this topic in further detail; nose in book and coffee in hand.

Cheers,

Andrew Flood

M.A.Sc. Student, 2nd Year

University of Toronto

References

[1] N.J. Ekins-Daukes, “Routes to High-Efficiency Photovoltaic Power Conversion,” in 2013 39th IEEE Photovoltaic Specialists Conference (PVSC), 2013.

[2] S. Fischer, A. Ivaturi, B. Fröhlich, M. Rüdiger, A. Richter, K. Krämer, B.S. Richards, and J.C. Goldschmidt, “Upconversion Silicon Solar Cell Devices for Efficient Utilization of Sub-Band-Gap Photons under Concentrated Solar Radiation,” in 2013 39th IEEE Photovoltaic Specialists Conference (PVSC), 2013.

[3] I. Kamiya, D.M. Tex, K. Shimomura, F. Yamada, K. Takabayashi1, and Y. Kanemitsu, “InAs Quantum Well Islands – a Novel Structure For Photon Up-conversion From the Near IR To the Visible,” in 2013 39th IEEE Photovoltaic Specialists Conference (PVSC), 2013.

[4] H. Han, C. Lin, H.C. Chen, Y. Tsai, Y. Yeh, H. Kuo, and P. Yu, “Spectrallu Dependent Performance of Hybrid Colloidal Quantum Dots GaAs Solar Cells,” in 2013 39th IEEE Photovoltaic Specialists Conference (PVSC), 2013.